What is Rapid Sheet Metal Fabrication?

Rapid sheet metal fabrication, also known as rapid prototyping sheet metal fabrication, is a manufacturing process that involves quickly creating custom metal parts or prototypes. This is done using computer-aided design (CAD) software and sheet metal fabrication equipment. This process is highly beneficial for companies that must rapidly design and create metal parts for testing, validation, or production.

Process of Rapid Sheet Metal Fabrication

The process of rapid sheet metal fabrication begins with a design file, which is created using CAD software. The file is then used to create a 3D model of the part or prototype. This model is then sent to a computer-controlled sheet metal fabrication machine, which uses precision cutting and bending techniques to form the component or prototype from a metal sheet.

Innovations in rapid sheet metal fabrication

In today’s fast-paced world, businesses are pressured to produce high-quality products quickly and efficiently. To meet these demands, new and innovative techniques are constantly being developed to improve the quality and efficiency of sheet metal fabrication.

Here are some of the most innovative techniques in rapid sheet metal fabrication:

Laser Cutting

Laser cutting is a fast and precise technique using a high-powered laser to cut through metal sheets. The laser beam is controlled by a computer, which allows for complex shapes and patterns to be cut quickly and accurately. This technique is ideal for creating intricate parts and figures that may be difficult or impossible to produce with other cutting methods.

Waterjet Cutting

Waterjet cutting is another technique that is gaining popularity in sheet metal fabrication. This process uses a high-pressure stream of water to cut through metal sheets, allowing for precise cuts and shapes. Waterjet cutting is also a cold-cutting process. There is no heat-affected zone, and the material is not subjected to thermal distortion or hardening.

3D Printing

3D printing is revolutionising the way we think about sheet metal fabrication. With 3D printing, a computer model creates a physical object by layering material on top of itself. This technique is ideal for creating complex geometries and shapes that would be difficult or impossible to produce with traditional sheet metal fabrication methods.

Automation

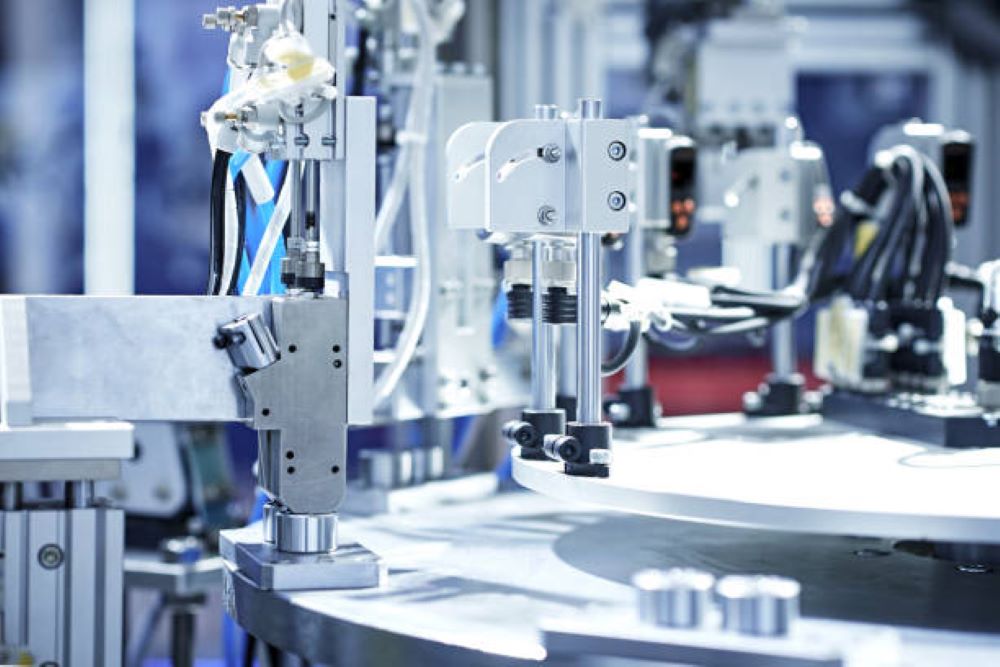

Automated sheet metal fabrication systems are becoming increasingly common in the industry. These systems use robots and other mechanical equipment to complete cutting, bending, and welding tasks. Automation can help improve quality and efficiency, eliminating the risk of human error and reducing production time.

Advanced Materials

Advancements in sheet metal materials are also improving the quality and efficiency of fabrication. New materials like high-strength alloys and lightweight composites offer improved strength-to-weight ratios, resulting in lighter and more efficient products. Additionally, new coatings and finishes can enhance the durability and lifespan of sheet metal products.

Conclusion

Rapid sheet metal fabrication is a highly effective and efficient manufacturing process that offers a range of benefits to companies that need to quickly produce custom metal parts or prototypes. This process is an ideal solution for companies looking to stay ahead of the curve and remain competitive in their respective industries. By adopting these techniques, businesses can stay ahead of the curve and produce high-quality products quickly and efficiently.